CA 02317932 2001-05-04

APPARATUS AND KIT FOR COUPLING

A SNOWMOBILE SUSPENSION

Field of Invention

This invention relates to snowmobile suspension systems, and more particularly

to

uncoupled suspension systems, and even more particularly to an apparatus, in

the form of an

after-market, upgrade kit, to convert an uncoupled suspension system to a

coupled suspension

system.

Background of the Invention

Tracked vehicles such as snowmobiles have rear suspension systems generally

consisting of front and rear suspension arms pivotally mounted on shafts,

which are rotatably

connected to the frame of the snowmobile. They also include a slide frame,

which comprises a

pair of laterally spaced apart slide rails or longitudinal skids

interconnected transversely on

opposing lateral sides of the machine. The slide rails are in sliding contact

with an endless belt

which contacts the snow surface contact drives the snowmobile. Front and rear

suspension arms

pivotally interconnect the chassis to the slide frame.

It is generally known in the art that independent movement of the front and

rear

suspension arms is less desirable than a suspension system in which the front

and rear suspension

arms are coupled. In an uncoupled suspension system, when the front suspension

arm deflects as

it contacts a bump, the independent rear suspension arms remains in its ride

or fully extended

position. This results in an angle of incidence between the slide rails and

the bump. Unless the

impact is so large that it compresses the rear suspension arm spring and shock

absorber

assembly, thereby flattening the angle of incidence, the slide rails will act

as a ramp forcing the

rear of the snowmobile upward. That is, with the slide rails angled in an

upward incline due to

CA 02317932 2001-05-04

the independent deflection of the front suspension arm, but not the rear

suspension arm, the

snowmobile will hop over the bump, imparting a secondary jolt which increases

in intensity with

the speed of the snowmobile. This secondary jolt also results in a loss of

control and a reduction

the speed of the snowmobile.

On the other hand, a coupled suspension system is one in which, for example,

the

rear portion of the suspension system reacts (i. e., is coupled) to the

compression experienced by

the front portion of the suspension system as the snowmobile passes over a

bump in the terrain.

In effect, the bump is « communicated » to the rear portion of the suspension,

causing the rear

portion to be pulled upward toward the chassis before the rear portion

actually reaches the bump.

This reduces the angle of incidence between the slide rail and the bump, which

thereby reduces

the secondary jolt experienced by the rider. As a result, a coupled suspension

system provides

for an improved ride because the coupled suspension is better suited to adjust

to varying terrain

conditions.

Manufacturers have developed a variety of ways to provide coupled suspension

systems,

1 S which typically involve restricting the amount of longitudinal movement of

the rear suspension

arm. Such system are shown in U.S. Patent Nos. 5,881,834, 5,692,579,

5,667,031, and

5,944,134.

Because a coupled suspension offers a superior ride than an uncoupled

suspension, those

skilled in the art of designing snowmobile suspensions have developed coupling

apparatuses that

may be added, as an after-market upgrade, to suspensions that are not coupled.

2

CA 02317932 2000-09-08

It is therefore the object of this invention to provide an apparatus, in the

form of an

after-market, upgrade kit, :for installation onto an uncoupled snowmobile

suspension system

that, when installed, converts the uncoupled suspension system into a coupled

suspension

system.

It is further an object of the present invention to provide an apparatus, in

the form of

an after-market, upgrade kit, specifically configured to be installed onto the

Arctic Cat ~ line

of snowmobiles.

Summary of the Invention

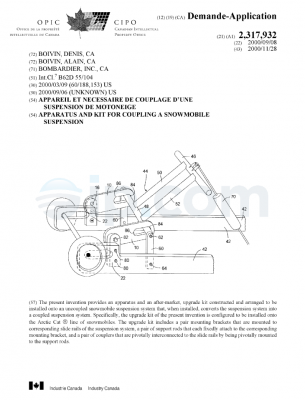

It is the object of the present invention, therefore, to provide an apparatus

~ and an

after-market, upgrade kit constructed and arranged to be installed onto an

uncoupled

snowmobile suspension system that, when installed, converts the suspension

system into a

coupled suspension system. Specifically, the upgrade kit of the present

invention is

configured to be installed onto the; Arctic Cat ~ line of snowmobiles. The

upgrade kit

includes a pair mounting brackets that are mounted to corresponding slide

rails of the

suspension system, a pair of support rods that each fixedly attach to the

corresponding

mounting bracket, and a paiir of couplers that are pivotally interconnected to

the slide rails by

being pivotally mounted to the support rods.

Other objects and advantages of the present invention will be realized in

accordance

with the following detailed description, appended drawings, and claims.

Brief Description of the Drawings

The various embodiments of the present invention are shown throughout the

drawings, in which:

3

CA 02317932 2000-09-08

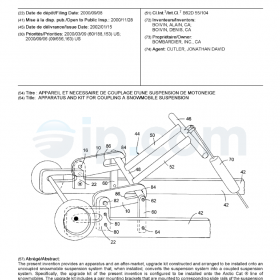

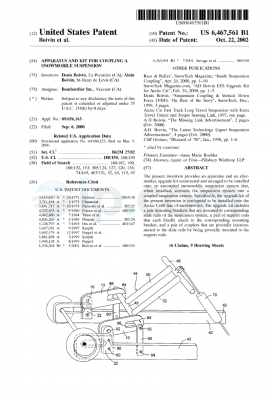

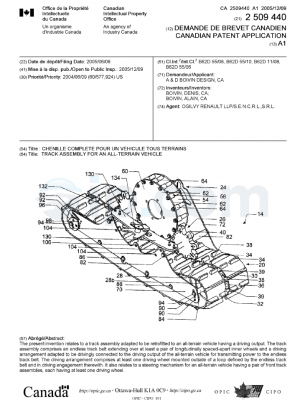

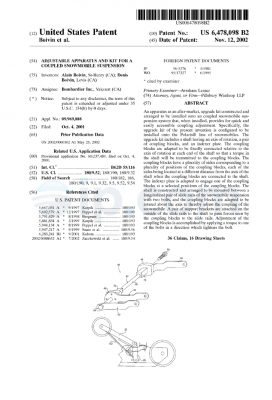

Fig. 1 is a perspective view of the preferred embodiment of the apparatus of

the

present invention after assembly but before attachment to the snowmobile

suspension;

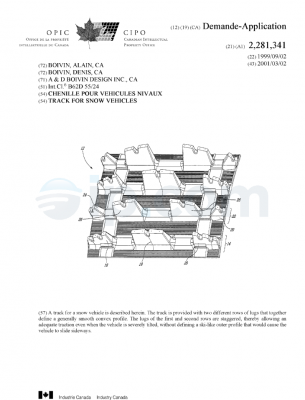

Fig. 2 is a plan view of a coupler of the upgrade kit of the preferred

embodiment;

Fig. 3 is an end view of a wring arm tube of the upgrade kit of the preferred

embodiment;

Fig. 4 is a side view of the swing arm tube of Fig. 3;

Fig. SA is a plan view of a flat plate of the upgrade kit of the preferred

embodiment;

Fig. SB is a cross-sectional side view of a flat plate of the upgrade kit of

the preferred

embodiment taken along section line SB-SB;

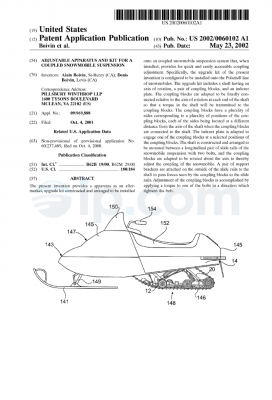

Fig. 6 is a perspective view of a portion of an Arctic Cat ~ snowmobile

suspension

system without the upgrade; kit installed;

Fig. 7 is a side view of a portion of the Arctic Cat ~ snowmobile suspension

system

of Fig. 6;

Fig. 8 is a perspective view of the upgrade kit of the preferred embodiment

installed

onto the Arctic Cat ~ snowmobile suspension system of Fig. 6;

Fig. 9 is a side view of the upgrade kit installed onto the Arctic Cat ~

snowmobile

suspension system of Fig. 8;

Fig. 10 is a top view of the upgrade kit installed onto the Arctic Cat ~

snowmobile

suspension system of Fig. 8;

Fig. 1 lA is a depiction of the; angle of incidence experienced by the slide

rails as the

snowmobile passes over a bump when the suspension system in uncoupled, i.e.,

the upgrade

kit is not installed; and

Fig. 11B is a depiction of the angle of incidence experienced by the slide

rails as the

snowmobile passes over a bump when the suspension system in coupled, i.e., the

upgrade kit

is installed.

4

CA 02317932 2000-09-08

Detailed Description

Referring now more particularly to the Figures, wherein the same reference

numbers

are used where applicable, the apparatus of the present invention, which is

also referred to as

an upgrade kit, is generally indicated at 5 and is illustrated in Fig. 1.

Generally, the upgrade

kit 5 is constructed and an-anged to be installed onto an uncoupled snowmobile

suspension

system, so that when installed, the suspension system becomes coupled. More

specifically,

the upgrade kit S is configured to be assembled onto the Arctic Cat ~ line of

snowmobiles

that are originally manufactured with uncoupled suspension systems, the

details of which are

described below.

Referring to the Figs. 1-5, the upgrade kit 5 comprises, among other

components, two

couplers 10, two support rods 16, and two mounting brackets 22. Figures 2-4

show each

component separately, and Fig. 1 shows the upgrade kit ~ assembled, but not

attached to the

suspension system. The support rods are hereinafter referred to as swing arm

tubes 16, and

the mounting brackets are hereinafter referred to as flat plates 22. As seen

in Fig. 2, the

couplers 10 are flat oblong elements with essentially circular holes 12 formed

therethrough at

one end and oblong holes 14 formed therethrough at opposite ends thereof.

Couplers 10 are

preferably made of an ultr;~-high molecular weight plastic, but any other

suitable material

may be used, as would be understood by those skilled in the art. The thickness

of the

couplers 10 will vary deper.~ding on the material used, but the thickness is

chosen to provide

suitable stiffness and strength. In the preferred embodiment where ultra-high

molecular

weight plastic is used, the thickness of couplers 10 is approximately 0.5

inches.

The upgrade kit 5 also includes the two swing arm tubes 16, an end view of

which is

illustrated in FIG. 3 and a :;ide view of which is shown in FIG. 4. Swing arm

tubes 16 are

5

CA 02317932 2000-09-08

essentially cylindrical, T-shaped elements with a hexagonal stop flange 18 at

one end. Swing

arm tubes 16 are provided with a. threaded bore 20 dawn the center thereof for

threaded

placement of a bolt 40 therein. Although the bore is shown passing through the

entire swing

arm tubes 16, the bore ca.r~ terminate at an intermediate position therein, as

long as the bore

can accommodate a bolt.

When the upgrade kit 5 is assembled (Fig. 1 ), swing arm tube 16 is inserted

into hole

12 of coupler 10 from an end opposite stop flange 18. The stop 18, which has

an average

outside diameter greater than hole 24, limits the transverse displacement of

coupler 10.

When assembled, the bore of hole:. 12 of couplers 10 are in rotational,

sliding contact with

outer, cylindrical surfaces 30 of tlae swing arm tubes 16. The cylindrical

surfaces 30 are

provided with a relatively smooth surface finish. The swing arm tubes 16 are

preferably

made of a corrosion-resistant, steel alloy material or from steel that has

been appropriately

treated so that it is corrosion resistant.

Referring to Fig. 5, the two :flat plates 22 are oblong elements with three

holes 24, 26,

and 28 formed therethrough. Holes. 26 and 28 are provided with recesses 30, 32

on one side

of plate 22 for receiving the; head of a bolt (not shown), and are used to

mount the plates 22 to

the slide rails 42, which are shown in Fig. 8. Holes 24 receive bolts 25 (Fig.

1), which

engage the threaded bore f.0 of swing arm tubes 16 to thereby fixedly attach

the swing arm

tubes thereto. Preferably, so that they do not add excessive weight to the

snowmobile and so

that they provide sufficient strength to couple the suspension, plates 22 are

made from

aluminum. However, any suitable material may be substituted therefor.

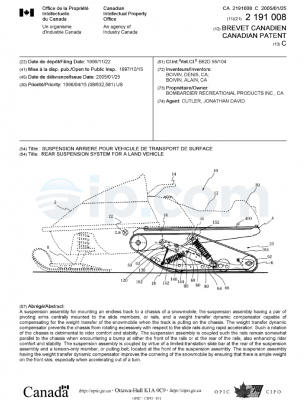

Referring now to Figs. 6 and 7, the couplers 10, swing arm tubes 16, and

aluminum

plates 22 are constructed arid arranged to be assembled and attached to the

sliding rails 42 of

an uncoupled snowmobile suspension system. More specifically, upgrade kit 5 is

configured

to be assembled onto an t~,rctic Cat ~ snowmobile suspension system, the rear

portion of

6

CA 02317932 2000-09-08

which is depicted, without the upgrade kit 5 attached, in Fig. 6. The

suspension system of the

Arctic Cat ~ includes slide rails 42 that are interconnected to the snowmobile

chassis (not

shown) by a rear suspension arm 44. The rear suspension arm 44 is a

trapezoidally-shaped

structure that includes a tra~.nsverse rear upper tube portion 46 and a

transverse rear lower tube

portion 48 that are conneci:ed by tyro tubes 50 and 52. The upper tube portion

46 of the rear

suspension arm is pivotally mounted on a first transverse shaft (not shown)

that is fixedly

attached to the chassis 38. Likewise, the lower tube portion 48 of the rear

suspension arm 44,

which extends downwardl3~ and rearwardly, is pivotally mounted on a second

transverse shaft

(not shown) that is fixedly attached to an end of lower arms 60 by bolts 62.

Lower arms 60,

in turn, are pivotally attached to the corresponding slide rails 42 by bolts

64. A shock

– absorber 70 extends fronn the upper tube portion 46 of the rear suspension

arm 44

downwardly and forwardly to fixedly connect to a lower transverse shaft (not

shown), which

is fixedly attached to slide rails 42. The suspension system further includes

a front

suspension arm (not shown) and a fiont shock absorber (not shown). As is known

in the art,

the Arctic Cat ~ suspension system described and shown above is uncoupled.

That is, the

front and rear suspension arms move independently from one another.

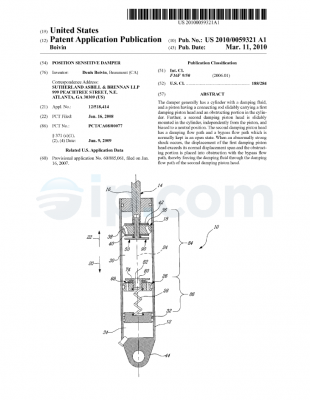

Referring now to Figs. 8-10, the attachment of upgrade kit 5 to the Arctic Cat

suspension system will now be described. Flat plates 22 are attached to the

interior of the

snowmobile slide rails 42 on either aide of the suspension, rearward of lower

arms 60. In the

preferred embodiment, the flat plates 22 are fixedly attached to slide rails

42 by being bolted

thereto with bolts 80 that p~~ss through corresponding through holes provided

in slide rails 42.

Bolts 80, nuts and lock washers (not shown) engage holes 26, 28 provided in

flat plates 22.

Bolts 80 may also be the Name bolts used to mount a track adjuster (not

shown), which is

mounted exteriorly on either side of the slide rails 42, as is known in the

art. Although shown

being bolted to the slide rails, the flat plates could also be fixedly

attached thereto by other

7

CA 02317932 2000-09-08

fastening mechanisms, such as welding or brazing. Additionally, flat plates 22

could be

integrally formed with slidt~ rails 42, rather than being separate, distinct

elements.

The plastic couplers 10 are pivotally interconnected to the flat plates 22 via

swing arm

tubes 16. Each swing army tube 16. is inserted into hole 12 of plastic

couplers 10, with the

stop flange 18 facing the interior of the suspension system, and fixedly

connected to flat plate

22 with bolts 82 and lock washers 83 (Fig. 1). Each cylindrical, swing arm

tube 16 thus

provides a pivot point for plastic couplers 10 to rotate. Because the length

of each swing arm

tube 16 is greater than the thickness of the plastic couplers 10, as best seen

in Fig. 10, the

plastic couplers can also slidingly translate in the transverse direction on

the cylindrical

surface 30 of swing arm tribes 16. The plastic couplers 10 are then connected

to the rear

swing arm 44 by removing bolt 62 ;end rotating lower arm 60 so that a free end

of tube 48 is

exposed. Each plastic coupler 10 is slipped over tube 48 through oblong slot

14, and the rear

swing arm 44 is reattached to lower arm 60.

Once assembled, thf; plastic couplers 10 couple the suspension system to

improve the

ride of the snowmobile. Prior to the installation of the upgrade kit, when the

snowmobile hits

a bump, as depicted in Fig. 11 A, the front of the slide rail compresses

before the rear of the

slide rail, and as the slide rails 42 move upward the rear suspension arm 44

pivots about a

shaft (not shown) fixedly attached b;y bolts 62. At the same time, lower arm

60 freely pivots

about bolt 64, and this pivoting movement of lower arm 60 is not limited in

either rotation

direction. Since lower arm 60 in unrestrained from rotational movement, the

suspension

system, without the upgrade. kit installed, is uncoupled. That is, as the

front of the rails hits a

bump, the front of the rails rise but the rear of the rails are still at the

bottom of the bump,

causing the rail to be presented at a specific angle of incidence 90 as the

rear of the rail

approaches the bump. The l;reater this angle of incidence is, the more

secondary kick there is

8

CA 02317932 2000-09-08

to the rider when the rear hits the bv.unp and the greater the loss of control

there is to the rider,

and the greater loss of speed of the vehicle.

With the upgrade kit 5 installed, as the front of the slide rails rise,

causing rotational

movement of the rear suspension arm 44 and lower arms 60, the lower arms 60

are restrained

from freely rotating due to the limitation imposed on it by plastic couplers

10. For example,

as the lower arm 60 rotates clockwise as shown in Fig. 6, it engages the

forward end 84 of

slots 14 and imparts a pulling force to the plastic coupler 10. Since plastic

couplers 10 are

interconnected to the slidE: rails 4:2, the rear of slide rails 42 are

correspondingly pulled

upward, as shown in Fig. 11 B. Thus, the suspension system becomes « front to

rear coupled »

with the upgrade kit installed. That is, as the front of the suspension hits a

bump, the front

« communicates » with the rear and i:orces (or pulls) the rear upward prior to

the rear actually

hitting the bump. This causes the rail to be presented at a specific angle of

incidence 92 as

the rear of the rail approached the bump, where the angle of incidence 92

(with coupling) is

less than the angle of incidence 90 (without coupling). This reduction in the

angle of

incidence as a result of the system being coupled with upgrade kit 5 reduces

secondary kick,

provides more control to the rider, and minimizes the loss of speed as the

snowmobile passes

over the bump.

Similarly, with the upgrade kit installed, the suspension system becomes « rear

to

front » coupled. Where the rider lands on the back of the snowmobile, after the

rear

suspension arm 44 has displaced the’ length of slot 14 to the rear, due to the

counterclockwise

rotation of lower arm 60 as shown in Fig. 6, further movement and rotation are

prevented by

the lower tube’s 48 engagement with a rearward end 86 of slot 14. This stopped

travel in the

rear suspension arm 44 cau;>es the front suspension arm (not shown), and thus

the front of the

slide rails, to start to displace upward. Thus, the suspension system becomes

coupled from

the rear to the front. Without the upgrade kit 5 installed, where the rider

lands on the back of

9

CA 02317932 2000-09-08

the snowmobile, the front suspension arm is independent of the rear arm and

only the rear

suspension arm 44 collapses.

Though not intended to be limiting, the dimensions of the components of

upgrade kit

5, which are sized for the P~rctic Cat ~ line of snowmobile suspensions, are

the following:

Table 1: Dimensions of upgrade kit components.

Plastic Couplers 10 (Fig. 2) dimension (inches)

L 1 2.875

L2 0.750

D 1 0.875

D2 1.000

R1 1.000

Swing arm tubes 16 (Fig. 4)

L3 1.000

L4 0.100

D3 0.875

Flat plates 22 (Figs., SA, SB;I

LS 1.500

L6 1.813

L7 1.250

D4 0.437

DS 0.250

D6 0.750

The upgrade kit 5 with the above dimensions is intended for the following

Arctic Cat ~ snowmobile models: the Z 440 (model years 1998 and 1999); the

entire ZL

series (model years 1998-2.000); the entire ZR series (model years 1997-2000);

the entire

ZRT series (model years 1997-2000); the Thunder Cat (model years 1998-2000);

the Cougar

DLX (model year 1998 only); and the EXT, EFI, DLX, and 600 (model year 1998

only).

CA 02317932 2000-09-08

However, as would be understood by those skilled in the art, there are

potentially other

snowmobile suspensions o,n which the present invention may be used.

While the invention has been described in connection with what is presently

considered to be the most practical and preferred embodiments, it is to be

understood that the

invention is not to be limited to the disclosed embodiments and elements, but,

to the contrary,

is intended to cover various modifications, combinations of features,

equivalent

arrangements, and equivalent elements included within the spirit and scope of

the appended

claims. Furthermore, the dimensions of features of various components provided

are not

meant to be limiting, and tlae size of the components can vary from the size

that is portrayed

in the figures and table herein in order to accommodate differently sized

suspension system

components.

English

English