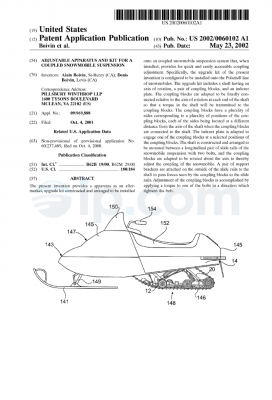

Canadian Application Publication

Title (French)

Chenille pour vehicules nivaux

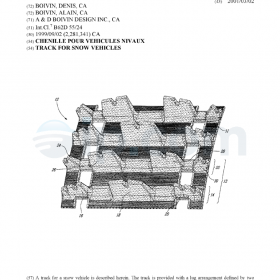

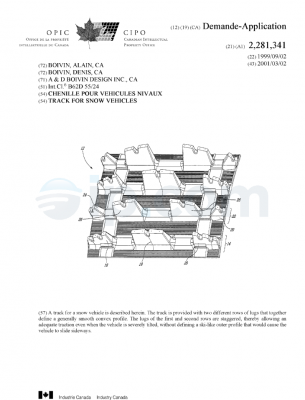

Abstract (English)

A track for a snow vehicle is described herein. The track is provided with a lug arrangement defined by two different rows of lugs that together define a generally smooth convex profile. The lugs of the first and second rows are staggered, thereby allowing an adequate traction even when the vehicle is severely tilted, without defining a ski-like outer profile that could cause the snow vehicle to slide sideways.

Inventors

BOIVIN, DENIS [+1] [-1]

BEAUMONT, Q1, CA

BOIVIN, ALAIN

ST-HENRI DE LÉVIS, Q1, CA

Applicants

A & D BOIVIN DESIGN INC.

LÉVIS, Q1, CA

Assignees

A & D BOIVIN DESIGN INC. [+3] [-3]

LÉVIS, Q1, CA

BOIVIN, DENIS

BEAUMONT, Q1, CA

BOIVIN, ALAIN

ST-HENRI DE LÉVIS, Q1, CA

CAMOPLAST INC.

SHERBROOKE, Q1, CA

Priority

US 654,160 A 01-Sep-2000 [+2] [-2]

CA 2281341 A 02-Sep-1999

CA 2317223 A 01-Sep-2000

Classifications

International (2006.01): B62D 55/27; B62D 55/24

International: B62D 55/24

Cooperative (2013.01.01): B62D 55/27; B62D 55/24

European: B62D 55/24; B62D 55/27

Language of Filing

English

Attorney, Agent or Firm

NORTON ROSE OR S.E.N.C.R.L., S.R.L./LLP

CA

CA 02317223 2000-09-O1

TITLE OF THE INVENTION

Track for snow vehicles

FIELD OF THE INVENTION

The present invention relates to snow vehicles. More

specifically, the present invention is concerned with a track for a snow

vehicle.

DESCRIPTION OF THE PRIOR ART

Endless tracks are well known in the art of snow

vehicles since they are particularly efficient at propelling a vehicle both on

soft and hard snow.

15 Conventional snowmobiles having relatively wide tracks

are also well known and many tracks have been designed for them over

the years. These conventional snowmobiles usually have a relatively long

seat that allow the snowmobiles to be ridden by two people: a driver and

a passenger. This, combined with the fact that snowmobiles are relatively

20 wide and provided with a heavy gasoline powered engine, make them

relatively bulky recreational vehicles.

A new type of recreational snow vehicle has been

proposed to overcome the bulkiness of the conventional snowmobile. It

CA 02317223 2000-09-O1

-2-

consists of a relatively narrow single-seater snowmobile type recreational

vehicle provided with an equally narrow track.

Such a recreational vehicle is described, for example, in

United States Patent No. 4,613,006, entitled « ENDLESS BELT DRIVEN

CYCLE », issued on September 23, 1986 to Alvin MOSS et al.. The vehicle

proposed by Moss is basically a motorcycle where the front wheel has

been replaced with a directing ski and the rear wheel has been replaced

with a drive arrangement provided with an endless track.

Moss et al. propose the use of an endless track provided

with a plurality of cleats spaced apart along an outer surface of the drive

track, wherein each of the cleats extends transversely of the track and has

a height, perpendicular to the outer surface of the track which increases

from opposite side edges of the outer surface to the longitudinal centerline

of the outer surface so that each of the cleats has a convex curved outer

peripheral surface.

A major drawback of the track described by Moss et al.

is the side to side continuity of the cleats. Indeed, this side to side

continuity forces Moss et al. to add outwardly projecting ribs extending

transversely of the cleats to counteract the lateral slippage of the drive

track. Since the convex cleats are continuous from one side to the other

of the track, they act as skis when the vehicle is banked for a turn, thereby

decreasing the stability of the vehicle.

CA 02317223 2000-09-O1

-3-

OBJECTS OF THE INVENTION

An object of the present invention is to provide an

improved track for snow vehicle.

SUMMARY OF THE INVENTION

More specifically, according to the present invention,

there is provided a track for snow vehicle comprising:

an endless belt provided with an external surface and

having a longitudinal axis; the endless belt also having a width delimited

by two opposite lateral sides;

a plurality of lug arrangements each including:

a first transverse row of lugs having at least

two first lugs mounted to the outer surface of the endless

belt;

a second transverse row of lugs having at

least two second lugs, the second row of lugs being so

mounted to the external surface of the endless belt as to

be longitudinally spaced apart from the first row of lugs;

wherein the first lugs and the second lugs are staggered and define a

generally smooth convex transverse outer surface.

Other objects, advantages and features of the present

invention will become more apparent upon reading of the following non

CA 02317223 2000-09-O1

-4-

restrictive description of preferred embodiments thereof, given by way of

example only with reference to the accompanying drawings.

BRIEF DESCRIPTION OF THE DRAWINGS

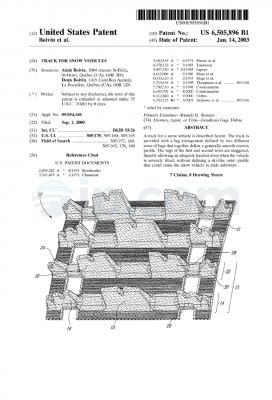

In the appended drawings:

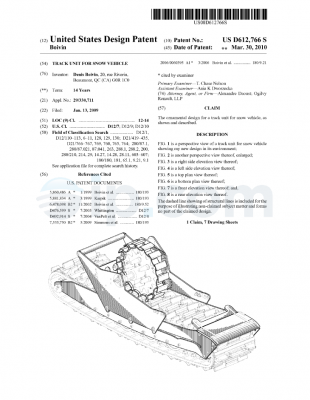

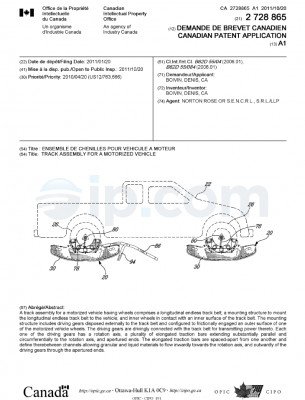

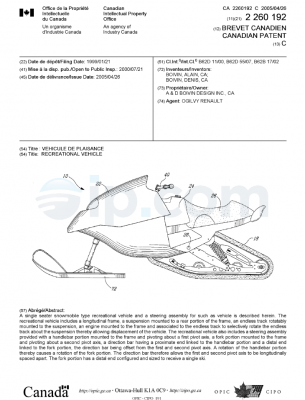

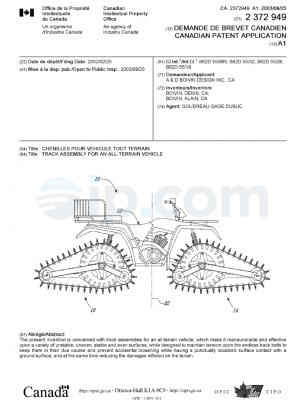

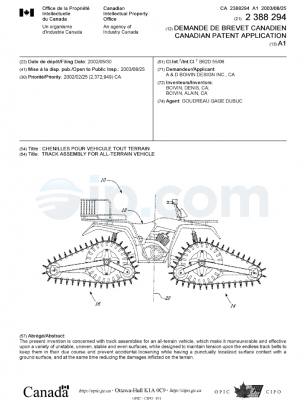

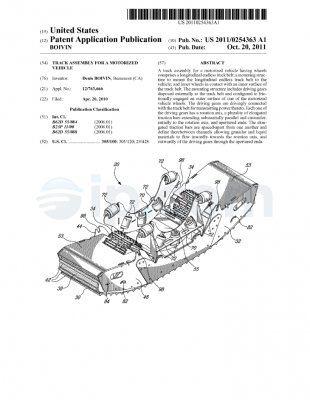

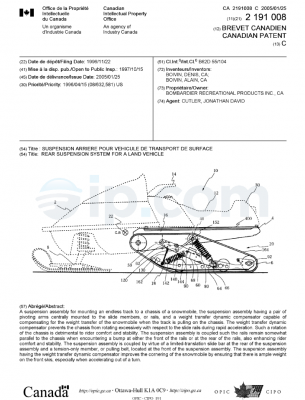

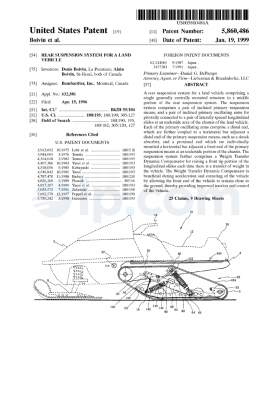

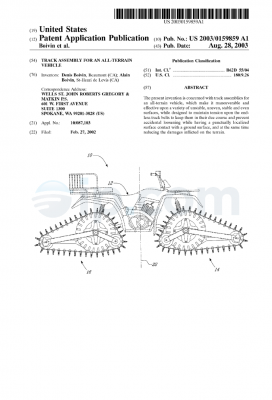

Figure 1 is a side elevational view of a recreational snow

vehicle provided with a track according to an embodiment of the present

invention;

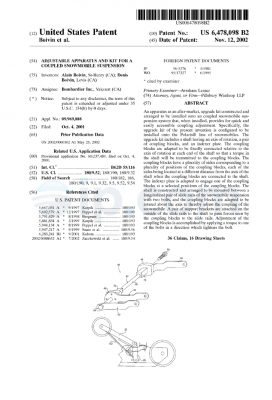

Figure 2 is a top plan view of the recreational snow

vehicle of Figure 1;

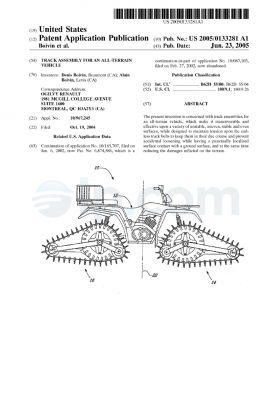

Figure 3 is a perspective view of a portion of a track

according to an embodiment of the present invention;

Figure 4 is a top plan view of the track of Figure 3;

Figure 5 is a sectional view taken along line 5-5 of

Figure 4, illustrating two adjacent rows of lugs;

Figure 6 is a sectional view similar to Figure 5 but

illustrating only one of the two different rows of lugs;

Figure 7 is a sectional view similar to Figure 5 but

illustrating only the other of the two different rows of lugs; and

Figure 8 is a sectional view taken along line 8-8 of

Figure 4, illustrating two adjacent rows of lugs.

CA 02317223 2000-09-O1

-5-

DESCRIPTION OF THE PREFERRED EMBODIMENT

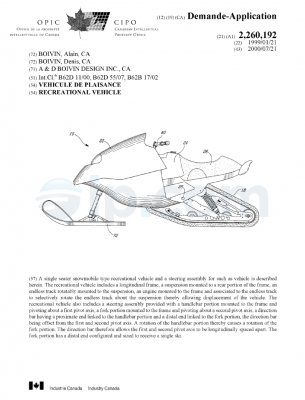

Figures 1 and 2 of the appended drawings illustrate a

recreational snow vehicle 10 provided with a track 12 according to an

embodiment of the present invention. As can be better seen from Figure

2, the snow vehicle 10, along with the endless track 12, is relatively

narrow, thereby allowing the vehicle 10 to be severely tilted during turns.

As will be understood by the following description, the

track 12 is designed to give a good traction even when the vehicle 10 is

tilted laterally, while preventing lateral slippage of the track 12 onto the

ground.

It is to be noted that the general features of snow

vehicles and of the endless tracks used to propel snow vehicles are

believed well known to one skilled in the art and will therefore not be

discussed herein.

Turning now to Figures 3-5 of the appended drawings,

the track 12 will be described.

The track 12 includes an endless belt 11 onto which a

plurality of lugs are mounted or integrally formed, as will be described

hereinbelow.

As can be seen from Figure 5, the overall profile of the

track 12, from one side to the other, i.e. transversely, is generally convex.

However, to overcome the above-noted drawback of the prior art, the

CA 02317223 2000-09-O1

-6-

convex profile of the track 12 is created by a lug arrangement 13

comprising two successive transverse rows of lugs arranged in a

staggered relationship, as illustrated in Figures 3 and 4.

A first transverse row of lugs 14 contains three lugs 16,

18 and 20 and a second row of lugs 22 contains four lugs 24, 26, 28 and

30. These lugs are symmetrical about a longitudinal axis 32 (see Figure

4).

A first lateral lug 16 of the first row 14 includes three

ground contacting surfaces 34, 36 and 38 separated by two indentations

10 40 and 42. The shape of lateral lug 16 is such that the ground contacting

surfaces 34, 36 and 38 are generally transversally convex.

A central lug 18 is centered about longitudinal axis 32

and includes two ground contacting surfaces 44 and 46, separated by an

indentation 48. The ground contacting surfaces 44 and 46 are

symmetrical about the longitudinal axis 32 and are generally transversally

convex.

A second lateral lug 20 is a mirror image of lug 16 about

the longitudinal axis 32.

As can be clearly seen from Figure 3, the first and

second lateral lugs 16 and 20 are laterally spaced apart from the central

lug 18.

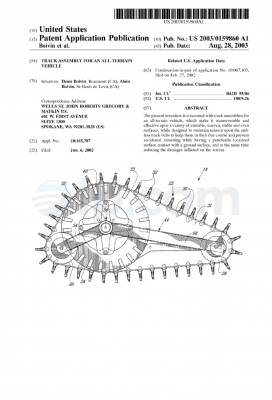

In the second transverse row of lugs 22, a first

intermediate lug 24 includes two ground contacting surfaces 50 and 52,

CA 02317223 2000-09-O1

-7-

separated by an indentation 54. The ground engaging surfaces 50 and 52

are slightly transversally convex.

A first external lug 26 includes two ground contacting

surfaces 56 and 58 that are separated by an indentation 60. As is

5 apparent from Figure 5, the ground contacting surfaces 56 and 58 are

transversally convex.

Finally, the second intermediate lug 28 and the second

external lug 30 are respectively mirror images of lugs 26 and 24 with

respect to the longitudinal axis 32. For concision purposes, these lugs will

10 not be further described herein.

Of course, the lug arrangement 13 defined by the rows

14 and 22 is repeated onto the entire external surface of the track 12.

As it is apparent from Figure 5, the ground contacting

surfaces of symmetrical lugs 24 and 30 are not aligned with the outer

15 surfaces of the outer lugs to form a continuous profile. Indeed, the ground

contacting surfaces of lugs 24 and 30 are more angled and exceed the

convex profile defined by the other lugs. This configuration of the outer

lugs is advantageous since it further prevents the vehicle from tipping over

during sharp turns at high speed when the vehicle 10 is severely tilted.

20 Turning now briefly to Figures 6 and 7 of the appended

drawings, another lateral slippage preventing feature will be described.

These figures illustrate the angular relationship between the ground

contacting surfaces 24, 38 and 58, in contact with the ground when the

vehicle is tilted laterally, and the side walls of the corresponding lugs.

CA 02317223 2000-09-O1

_$_

Since these angles are 90 degrees, the friction between the side of the

lugs and the ground prevent the vehicle from sliding laterally. Figures 6

and 7 also illustrate that the angular relationship between the ground

contacting surfaces 34, 36 and 56 and the respective indentations 40, 42

and 60 is also 90 degrees for the same reasons.

Furthermore, as will be understood by one skilled in the

art from the inspection of the different ground representing lines of these

figures, the vehicle provided with a track 12 is stable at many tilt angles.

It is therefore an advantage to design a track 12 where the ground

10 contacting surfaces are provided at various angles as illustrated and

described herein.

Turning Finally to Figure 8 of the appended drawings,

which is a sectional view taken along line 8-8 of Figure 4, a third lateral

slippage preventing feature will be described.

15 As is well known to those skilled in the art of endless

tracks for vehicles, metallic of fibre inserts are usually embedded under

the rows of lugs, in the rubber forming the endless belt. Conventionally,

these inserts cover essentially the entire width of the belt, leaving only a

minute amount of rubber at both ends for concealment purposes.

20 As can be clearly seen from Figure 8, the inserts 62

(only one shown) do not cover the entire width of the track 12 but leave

the sides of the track 12 free to flex. Again, this improves the grip

between the track and the ground during severe turns since it allows the

lugs 24 and 30 to flex more easily while keeping the lugs 16 and 20

CA 02317223 2000-09-O1

_g_

reasonably stiff since the inserts 62 runs under a sizable portion of these

lugs 16 and 20.

It is to be noted that each ground contacting surface

may be provided with a metallic insert, usually in the form of a fastener

(not shown), fixedly mounted to lugs ground engaging surfaces to

increase the friction between the track 12 and the ground in some

conditions.

One of ordinary skills in the art will readily understand

that the track 12, when mounted to a snow vehicle, has the advantage of

providing an adequate traction even when the vehicle is severely tilted,

without defining a ski-like outer profile that could cause the vehicle to

slide

sideways.

It is finally to be noted that the number of different rows,

the number of lugs on each row and the number of ground engaging

surfaces on each lug could be different from the above description without

departing from the spirit and nature of the present invention.

Although the present invention has been described

hereinabove by way of preferred embodiments thereof, it can be modified,

without departing from the spirit and nature of the subject invention as

defined in the appended claims.

(Source: IFI)

1. A track for snow vehicle comprising:

an endless belt provided with an external surface and

having a longitudinal axis; said endless belt also having a width delimited

by two opposite lateral sides;

a plurality of lug arrangements each including:

a first transverse row of lugs having at least

two first lugs mounted to said outer surface of said

endless belt;

a second transverse row of lugs having at

least two second lugs, said second row of lugs being so

mounted to said external surface of said endless belt as

to be longitudinally spaced apart from said first row of

lugs;

wherein said first lugs and said second lugs are staggered and define a

generally smooth convex transverse outer surface.

2. A track for snow vehicle as recited in claim 1, wherein

said at least two first lugs includes a central lug and two lateral lugs; each

said first lateral lug being transversely spaced apart from said central lug.

3. A track for snow vehicle as recited in claim 2, wherein

said at least two second lugs includes two intermediate lugs symmetrically

positioned about said longitudinal axis, and two external lugs

symmetrically positioned about said longitudinal axis.

4. A track for snow vehicle as recited in claim 3, wherein

each said two intermediate lugs is so positioned as to be longitudinally

aligned with a free space provided between said central lug and a

respective lateral lug of said first transverse row of lugs.

5. A track for snow vehicle as recited in claim 2, wherein

each said lateral lug includes at least one ground contacting surface and

a side wall joining said at least one ground contacting surface and said

external surface of said endless belt; one of said at least one ground

contacting surface defining, with said side wall, an angle of about 90

degrees.

6. A track for snow vehicle as recited in claim 3, wherein

each said intermediate lug includes at least one ground contacting surface

and a side wall joining said at least one ground contacting surface and

said external surface of said endless belt; one of said at least one ground

contacting surface defining, with said side wall, an angle of about 90

degrees.

7. A track for snow vehicle as recited in claim 3, wherein

each said external lug includes at least one ground contacting surface and

a side wall joining said at least one ground contacting surface and said

external surface of said endless belt; one of said at least one ground

contacting surface defining, with said side wall, an angle of about 90

degrees.

8. A track for snow vehicle as recited in claim 1, wherein

said at least two second lugs includes two external lugs symmetrically

positioned about said longitudinal axis; said two external lugs having such

a height that they exceed from said generally smooth convex transverse

outer surface of the lug arrangement.

9. A track for snow vehicle as recited in claim 1, wherein

each said row of lugs includes an insert embedded in the material forming

the endless belt; said insert being so sized as to cover a portion of said

width of said endless belt.

(Source: IFI)

English

English