CA 02388294 2002-05-30

1

TITLE OF THE INVENTION

Track assembly for an all-terrain vehicle

FIELD OF THE INVENTION[0001] The present invention relates to all-terrain vehicles. More

specifically, the present invention is concerned with track assemblies for an

all-

terrain vehicle.

BACKGROUND OF THE INVENTION

(0002] Traditionally, two types of all-terrain vehicles are proposed

either the wheel type or the tracked type.

[0003) Generally, a wheeled vehicle is more maneuverable than a

tracked vehicle, but is not as efficient on uneven or soft terrain such as,

for

example snow.

[0004] Tracked all-terrain vehicles have been proposed, which

require complicated track assemblies comprising a track frame to maintain the

tension of the endless track belt and prevent it from loosening. Furthermore,

such vehicles have generally a large contact area with the ground, which

results in a decreased maneuverability and an increased impact on the often

soft terrain.

[0005] Therefore, there is still room for improvements toward an all-

terrain vehicle provided with track assemblies, which is maneuverable and

effective upon a variety of unstable or uneven surfaces, while designed to

maintain tension upon the endless track belts to keep them in their due course

CA 02388294 2002-05-30

2

and prevent accidental loosening, and at the same time reducing the damages

inflicted on the terrain.

OBJECTS OF THE INVENTION

[0006] An object of the present invention is therefore to provide

improved track assemblies for an all-terrain vehicle.

SUMMARY OF THE INVENTION

(0007] More specifically, in accordance with the present invention,

there is provided an all-terrain vehicle comprising at least two track

assemblies

to support the all-terrain vehicle onto a ground surface, each one of said at

least two track assemblies comprising:

a longitudinal endless track belt provided with an inner

surface provided with a plurality of inner lugs and an outer surface provided

with a plurality of external lugs;

a mounting structure to mount said longitudinal endless track

belt to said vehicle,

wherein, when mounted to said mounting structure, said

longitudinal endless track belt has a punctually localized surface contact

with

the ground surface.

[0008] In accordance with another aspect of the present invention,

there is provided an endless track belt assembly comprising:

a track driving wheel provided with a plurality of teeth;

an endless track belt provided with an inner surface having a

plurality of inner lugs and an outer surface having a plurality of external

lugs,

said endless track belt being wounded around said track driving wheel;

CA 02388294 2002-05-30

3

wherein a) said teeth are so spaced that a distance between

two consecutive teeth spans a distance separating two consecutive inner lugs

of said endless track belt and b) said endless track belt, when mounted to

said

track riving wheel, has a punctually localized contact with a ground surface.

[0009] In accordance with another aspect of the present invention,

there is provided a method for mounting an endless track belt on a all-terrain

vehicle, comprising the acts of:

providing an endless track belt having inner lugs and external

lugs;

providing a track driving wheel having a plurality of teeth so

spaced that a distance between two consecutive of the plurality of teeth spans

a distance separating two consecutive of a plurality of inner lugs of the

endless

track belt;

interconnecting the track driving wheel to an inside idler

wheel and to an outside idler wheel; and

tensioning the endless track belt around the track driving

wheel, the inside idler wheel and the outside idler wheel so that the endless

track belt has a punctually localized surface contact with a ground surface.

(0010] Other objects, advantages and features of the present

invention will become more apparent upon reading of the following non-

restrictive description of preferred embodiments thereof, given by way of

example only with reference to the accompanying drawings.

BRIEF DESCRIPTION OF THE DRAWINGS

[0011] In the appended drawings:

CA 02388294 2002-05-30

4

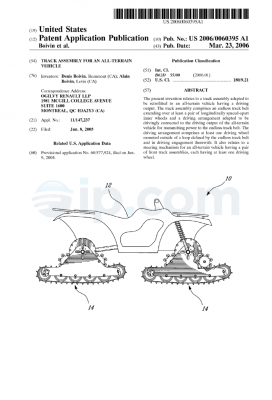

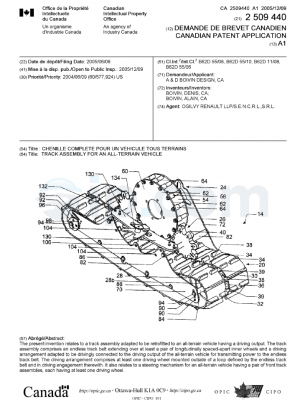

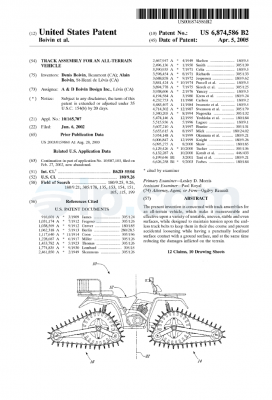

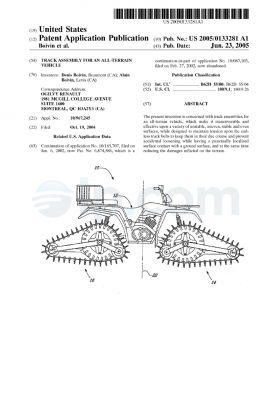

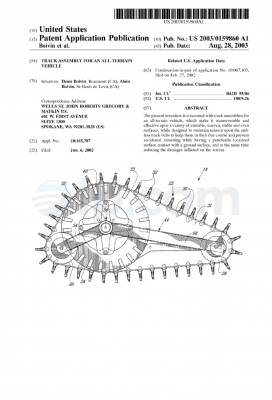

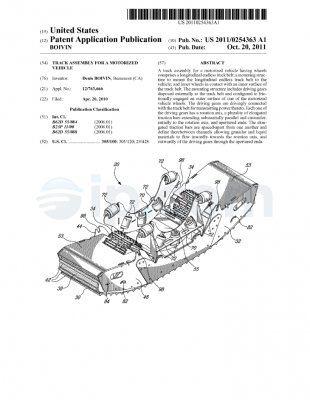

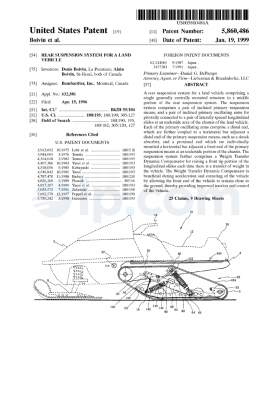

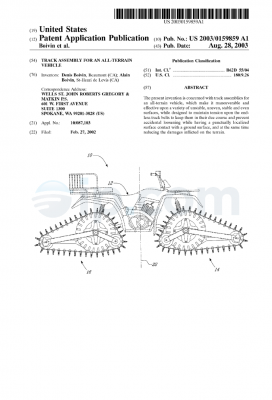

[0012] Figure 1 is a side elevational view of an all-terrain vehicle

provided with track assemblies according to an embodiment of the present

invention;

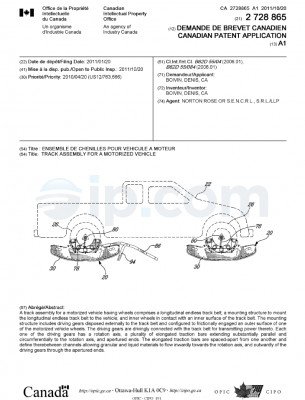

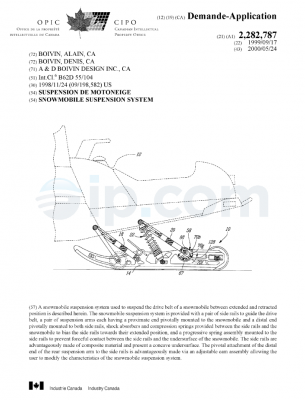

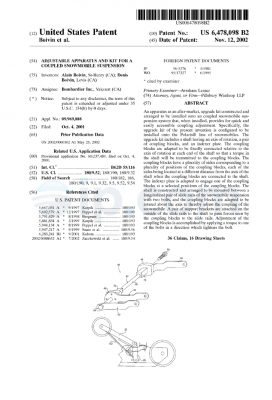

[0013] Figure 2 is a side elevational view of the front track assembly

of the vehicle of Figure 1, seen from of the outside of the all-terrain

vehicle;

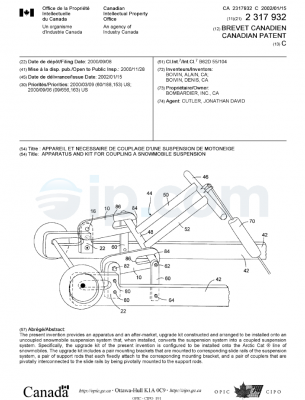

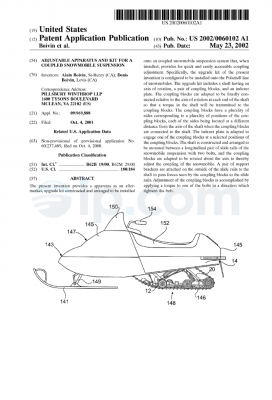

[0014] Figure 3 is a side elevational view of the front track assembly

of the vehicle of Figure 1, seen form the inside of the all-terrain vehicle;

[0015] Figure 4 is a sectional view taken along the line 4-4 of Figure

3;

[0016] Figure 5 is an enlarged side view of an outside idler wheel

attachment of the track assembly of Figure 2;

[0017] Figure 6 is a sectional view of a rigid member of the track

assembly of Figure 2;

[0018] Figure 7 is a top plan view of the attachment of the front track

assembly of Figure 1 to the all-terrain vehicle;

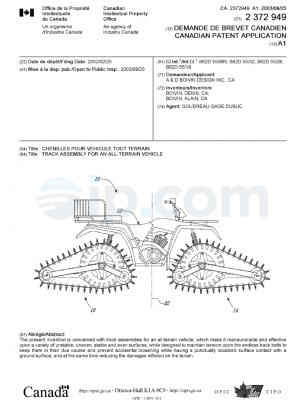

[0019] Figure 8 is a side elevational view of a rear track assembly of

Figure 1, seen from the inside of the all-terrain vehicle;

[0020] Figure 9 is a top plan view of the attachment of the rear track

assembly of Figure 1 to the all-terrain vehicle;

CA 02388294 2002-05-30

(0021) Figure 10 is a sectional view similar to Figure 4 but illustrating

a second type of endless track; and

[0022) Figure 11 is a sectional view similar to Figure 4 but illusfirating

a third type of endless track.

DESGRIPTION OF THE EMBODIMENT

[0023) A track assembly for an all-terrain vehicle according to an

embodiment of the present invention will now be described in details with

reference to the appended drawings.

(0024) Figure 1 shows an all-terrain vehicle 10 comprising a body 12

and four track assemblies (only two shown) according to the present invention

arranged in a plane adjacent to each side of the vehicle 10.

[0025) There are two identical track assemblies in the front of the all-

terrain vehicle 10, of which only one track assembly 14 is visible in Figure

1, in

place of conventional front wheels. Similarly, there are two identical track

assemblies, of which only one track assembly 16 is visible in Figure 1, in

place

of the conventional rear wheels.

[0026) Only the track assemblies 14 and 16 visible in Figure 1 will be

described hereinbelow. Furthermore, as they are symmetrical about a vertical

axis 22 when viewed from the outside of the vehicle 10 (see Figure 1 ), only

the

track assemblies 14 will be described hereinbelow. It is also to be noted that

the elements as seen from the outside of the vehicle 10 will bear the same

CA 02388294 2002-05-30

6

numbers in the rear track assembly 16 than the corresponding ones in the front

track assembly 14, with a prime.

[0027] However, since the attachment of rear and front track

assemblies differs as seen from the inside of the vehicles 10, they will be

described separately.

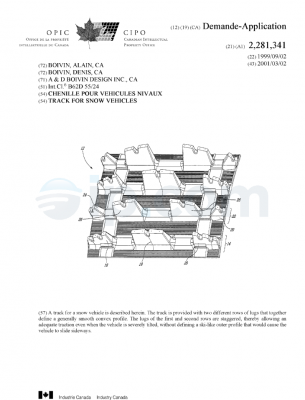

[0028] The front track assembly 14 is better seen in Figure 2. It

comprises a longitudinal endless track belt 23 and a mounting structure to

mount the endless track belt 23 to the vehicle 10. The mounting structure

includes a track driving wheel 24, a pair of inside idler wheels 26, a pair of

outside idler wheels 28 and supports to interconnect the wheels 24, 26 and 28

as will be described hereinbelow.

(0029] The endless track belt 23 is provided with inner lugs 30 on its

inner surface 31 and with external lugs 32 on its outer surface 33. It is

wounded

around the track driving wheel 24 and the idler wheels 28 and 26.

[0030] As can be better seen from Figure 4, the track driving wheel

24 is mounted to a conventional hub 35 of the all-terrain vehicle 10. The

wheel

24 includes a first mounting plate 37 mounted to the hub 35 and a second

mounting plate 34 mounted to the first plate 37 via four bolt and spacer

assemblies 36. A circular disk 38 is mounted to the bolt and spacer assemblies

36 and includes equidistant wide teeth 40 contacting the inner surface 31 of

the

track 23.

(0031] As will be apparent to one skilled in the art, the equidistant

teeth 40 are so located as to cooperate with some of the inner lugs 30 of the

endless track belt 23. More precisely, as can be better seen from Figure 2,

the

CA 02388294 2002-05-30

7

teeth 40 are spaced so that the distance between two consecutive teeth 40

spans the distance separating consecutive inner lugs 30 of the endless track

belt 23, in a meshing engagement, in such a way as to drive the endless track

belt 23.

(0032] Each of the inside idler wheels 26 includes a peripheral

portion in contact with the internal surface 31 of the track 23. The wheels 26

are interconnected by a spacing element (not shown).

[0033] Similarly, each outer idler wheel 28 includes a peripheral

portion in contact with the internal surface 31 of the track 23. The wheels 28

are interconnected by a spacing element 42.

[0034] The wheels 24, 26 and 28 are interconnected, as seen from

the outside of the track assembly 14, by an angled connecting element 44. The

angled connecting element 44 has a center portion 46 provided with an

aperture 48 in which bearings 50 are mounted. A fastener 52 connects the

connecting element 44 to the second plate 34 while allowing the angled

connecting element 44 to pivot about the fastener.

[0035] The connecting element 44 has a short arm 54 having a free

end to which the inside idler wheels 26 are rotatably mounted. The connecting

element 44 also has a long arm 56 having a free end to which the inside idler

wheels 28 are rotatably mounted as will be further discussed hereinbelow. The

connecting element 44 is better seen from the top plan view of Figure 6.

[0036] Turning now briefly to Figure 3 of the appended drawings, as

can be seen from the inside of the all-terrain vehicle 10, the idler wheels 26

and

28 of the front track assembly 14 are also directly connected together by an

CA 02388294 2002-05-30

elbowed connection element 58. The inside idler wheels 26 are rotatably

mounted to a first end of the elbowed connection element 58 while the outside

idler wheels 28 are rotatably mounted to a second end of the elbowed

connection element 58.

[0037] The rotatable connection of the outside idler wheels 28 to the

angle connection element 44 and to the elbowed connection element 58 will

now be described with reference to Figure 5.

[0038] As will easily be understood by one skilled in the art upon

inspection of Figure 5, the tension of the endless track belt 23 is adjusted

by

the connection of the outside idler wheels 28 to the elements 44 and 58. For

concision purpose, only the connection of the wheels 28 to the elbowed

connection element 58 will be described.

[0039] With reference to the enlarged side view of Figure 5, a

tension adjusting assembly according to another aspect of the present

invention will be described. As can be seen from this figure, a distal end of

the

connection element 58 includes a slotted aperture 60 receiving a fastener 62

used to rotatably mount the wheels 28 to the assembly. By sliding the fastener

62 in the aperture 60, it is possible to increase or decrease the tension on

the

track 23. To adjust and maintain this track tension, a cam element 64, having

an outer periphery provided with notches 66 located at different distances

from

the attachment point of the element 64, is mounted to the fastener 62. By

selecting which notch 66 is in contact with a fixed pin 68 of the element 58,

a

predetermined tension may be maintained. It is to be noted that the cam

element 64 is provided with a handle 70 to facilitate the manipulation by a

user.

CA 02388294 2002-05-30

9

[0040] Returning to Figure 4 of the appended drawings the endless

track 23 will be described in greater detail.

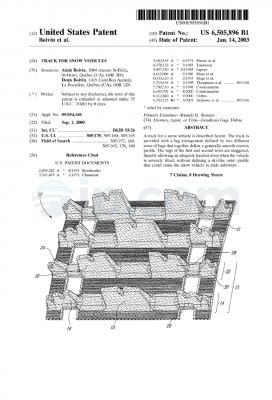

[0041] As can be seen from Figure 4, the overall profile of the track

23, from one side to the other, i.e. transversely, is generally convex.

However,

the convex profile of the track 23 is created by a lug arrangement comprising

two successive transverse rows of lugs arranged in a staggered relationship.

[0042] A first transverse row of lugs contains three lugs 72, 74 and

76 and a second row of lugs contains four lugs 78, 80, 82 and 84. These lugs

are symmetrical about a longitudinal axis (not shown).

[0043] A first lateral lug 72 of the first row includes three ground-

contacting surfaces separated by two indentations. The shape of lateral lug 72

is such that the ground contacting surfaces are generally transversally

convex.

[0044] A central lug 74 is centered about longitudinal axis and

includes two ground-contacting surfaces separated by an indentation. The

ground contacting surfaces are symmetrical about the longitudinal axis and are

generally transversally convex.

[0045] A second lateral lug 76 is a mirror image of lug 72 about the

longitudinal axis.

[0046] The first and second lateral lugs 72 and 76 are laterally

spaced apart from the central lug 74.

CA 02388294 2002-05-30

[0047] In the second transverse row of lugs, a first intermediate lug

80 includes two ground-contacting surfaces separated by an indentation. The

ground engaging surfaces are slightly transversally convex.

[0048] A first external lug 78 includes two ground-contacting

surfaces that are separated by an indentation and are transversally convex.

[0049] Finally, the second intermediate lug 82 and the second

external lug 84 are respectively mirror images of lugs 80 and 78 with respect

to

the longitudinal axis. For concision purposes, these lugs will not be further

described herein.

[0050] Of course, the sequences described hereinabove of the lug

arrangement defined by the rows of lugs are repeated onto the entire external

surface of the endless track 23.

[0051] The endless track belt 23 further includes, for each row of

lugs, a stiffening rod 71, made of glass fibers for example. Each stiffening

rod

71 is embedded in the material forming the track belt 23 so as to be generally

parallel to the inner surface 31 thereof. The rods 71 provide enhanced

rigidity

to the endless track belt 23. The enhanced rigidity of the track belt 23 has

many

advantages. For example, it helps the track to provide adequate traction even

when the center portion of the track is not in direct contact with the ground,

as

illustrated in Figure 4. However, it has been found that this type of traction

may

be detrimental to the steering of the vehicle in some conditions.

[0052] As it is apparent from Figure 4 the ground contacting surtaces

of symmetrical lugs 78 and 84 are not aligned with the outer surfaces of the

other lugs to form a continuous profile. Indeed, the ground contacting

surfaces

CA 02388294 2002-05-30

11

of lugs 78 and 84 are more angled and exceed the convex profile defined by

the other lugs. This configuration of the outer lugs is advantageous since it

further prevents the vehicle from tipping over during sharp turns at high

speed

when the vehicle 10 is severely tilted.

[0053] As mentioned hereinabove, the way the front track assembly

14 is attached to the body 12 of the vehicle 10 differs from the way the rear

track assembly 16 is attached to the body 12 of the vehicle 10. These two

attachments will be described hereinbelow.

[0054] The front track assembly 14 is attached to the body 12 of the

vehicle 10 in a fashion shown in Figures 4 and 7, while the rear track

assembly

16 is attached to the body 12 of the vehicle 10 in a fashion shown in Figure 8

and 9.

[0055] As seen in Figures 4 and 7, the front track assembly 14 is

mounted to a tubular wheel table 100 of the vehicle 10 by means of a generally

triangular plate 102 fastened thereto by a plurality of U-bolts 104, 106, 108

and

110. A rod 112 is connected between the elbowed connection element 58 and

a pivot 114 of the tubular wheel table 100. A first end of the rod 112 is

attached

to the elbowed connection element 58 by means of rubber damping elements

116, in such a way as to allow a vertical movement at this point of the rod

112

in relation to the elbowed connection element 58. A second end of the rod 112

is attached to the pivot 114 of the tubular wheel table 100 by means of an R-

clip 120, in such a way as to allow at this point a horizontal movement of the

plate 102 holding the tubular wheel table 100 relative to the elbowed

connection element 58.

CA 02388294 2002-05-30

12

[0056] The front track assembly 14 is further attached to the body 12

of the vehicle 10 through a conventional rod 150 of the suspension system of

the vehicle 10 and a conventional rod 157 used for direction (see Figure 4).

[0057] As seen in Figures 8 and 9, the rear track assembly 16 is

mounted to the body 12 of the vehicle 10 by a rod 212. The rod 212 is

connected on a first end to the elbowed connection element 58′ by means of a

rubber damping attachment 216. It is attached, on a second end, to a tubular

chassis 130 of the body 12 of the vehicle 10 by means of a chipping joint 132

fastened thereto by an R-clip 134.

[0058] From the above description of the fashion in which the front

and rear track assemblies 14 and 16 are mounted to the body 12 of the vehicle

10, in relation to Figures 4 and 7, and 8 and 9 respectively, the present

invention provides for track assemblies that are easily removed or mounted to

the vehicle 10, through using R-clips (120 and 134), which enable

disconnecting the track assemblies from the vehicle in a simple manner.

[0059] As stated hereinabove, the interior surface 31 of the endless

track belt 23 is provided with a plurality of equally spaced lugs 30, which

ensure

a positive engagement with the teeth 40 provided on the outer circumference of

the wheel 24. In operation, the wheel 24 is coupled to a drive shaft, via the

hub

30, connected to an engine (not shown), in such a way that the engine drives

the wheel 24 in rotation. The wheel 24 thus drives the endless track belt 23

by

the meshing engagement of the teeth 40 with the internal lugs 30 of the

endless track belt 23.

[0060] It is further to be understood that the external lugs 32 on the

external circumference surface of the endless track belt 23 respectively exert

a

CA 02388294 2002-05-30

13

positive mechanical connection with the underlying ground surface that

contributes to propel the vehicle 10.

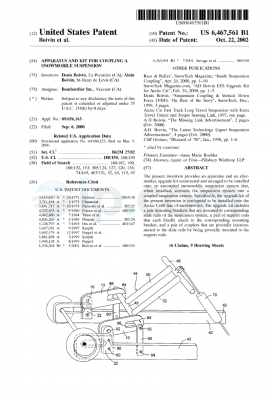

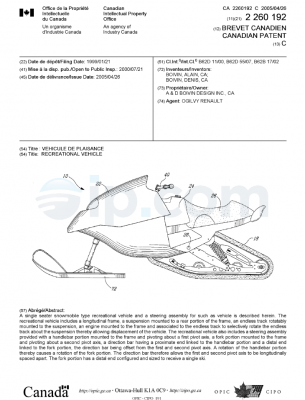

[0061] Figure 10 and Figure 11 show sectional views similar to that

of Figure 4 but illustrating variants of an endless track that may be mounted

to

the track assembly of the present invention.

[0062] In Figure 10, the overall profile of the endless track belt 23a,

from one side to the other, i.e. transversely, is generally convex.

[0063] The convex profile of the endless track belt 23a is created by

the same lug arrangement as that described hereinabove in relation to Figure

4. In this specific embodiment however, the endless track belt 23a does not

include stiffening rods under each row of lugs. Consequently, the rigidity of

the

endless track belt 23a is less than the rigidity of the endless track belt 23

(Figure 4) and the profile of the endless track belt 23a conforms itself to

the

profile of the ground. Since the pressure is more localized in the center of

the

endless track belt 23a, a more punctually localized contact zone between the

endless track belt 23a and the ground 29 is created. In many cases, this

punctually localized contact zone makes the vehicle 10 more maneuverable.

[0064] Turning now to Figure 11, a third version of an endless track

belt 23b will be described. The endless track belt 23b is wounded around the

track driving wheel 24 and the idler wheels 28 and 26, is still provided with

inner lugs 30 on its inner surface 31. However, its outer surface is provided

with

rectangular lugs 86. Since there are no stiffening rods in the endless track

belt

23b, the endless track belt 23b is free to conform itself to the ground 29, as

seen in Figure 11. Furthermore, since the pressure is exerted only in the

middle

CA 02388294 2002-05-30

14

of the endless track belt 23b by the wide teeth 40, a punctually localized

contact zone between the endless track belt 23b and the ground 29 is created.

[0065] As will be apparent to one skilled in the art, the endless track

belts 23a has a particularly punctually localized contact surface with the

ground

29. Indeed, since it is transversally convex, it generally contacts the ground

29

with a limited surface at any given time when the ground 29 is hard.

[0066] Furthermore, since there are no guiding rails for the endless

track belts 23, 23a or 23b, the external lugs only exert a pressure on the

ground 29, when it is hard, in the vicinity of the wide teeth 40 if the wheel

24.

These two combined features improve the maneuverability of the vehicle since

it emulates the contact of a conventional tire onto hard ground, given that a

shortened length of contact of the endless track with the ground surface

reduces the resistance to a turning force.

[0067] Of course, one skilled in the art could designed another

convex profile of the external lugs of the endless track belts 23 and/or

another

arrangement of the mounting assembly of the endless track belts 23 to the

vehicle 10 to obtain this « one point contact » feature without departing from

the

spirit and nature of the present invention. For example, one could provide a

guiding rail having a convex profile and transversally convex lugs to achieve

similar results.

[0068] As people in the art will understand, the all-terrain vehicle of

the present invention, provided with four endless track assemblies, can be

used

for a wide range of operations and terrain, while being highly mobile and

offering good running performance.

CA 02388294 2002-05-30

[0069] The endless track structure maintains an adequate

configuration over a variety of surfaces.

[0070] It will be obvious to people skilled in the art that the present

invention can be applied both in the case of a two-wheel drive vehicle wherein

the power is typically applied only to the rear track belt assemblies and the

front

track assemblies merely facilitate steering, and in the case of a four-wheel

vehicle, wherein power is independently provided to each one of the four track

assemblies.

[0071] As will be further understood by one skilled in the art, the all-

terrain vehicle 10, equipped with track assemblies according to the present

invention, may be viewed as a snow vehicle since it may be used on snow as

efficiently as conventional snow vehicles such as snowmobiles, for example.

However, the one-point contact feature of the present invention allows the use

of the all-terrain vehicle on harder surface without the usual drawbacks of

tracked vehicles.

[0072] Interestingly, the present track assembly system can equip all

four wheels of an all-terrain vehicle or only the front or rear wheels

thereof,

since it only weakly reduces the speed of the vehicle relative to the

underground surface.

[0073] A further possibility would be to use track assemblies

according to the present invention in place of the rear wheels of a vehicle,

while

mounting skis in place of the front wheels thereof.

[0074] Although the present invention has been described

hereinabove by way of preferred embodiments thereof, it can be modified,

CA 02388294 2002-05-30

16

without departing from the spirit and nature of the subject invention as

defined

in the appended claims.

English

English